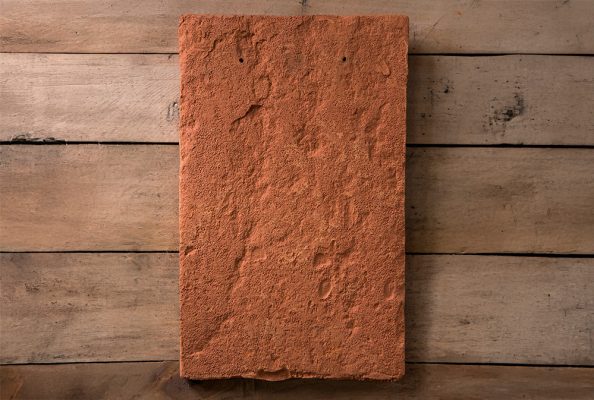

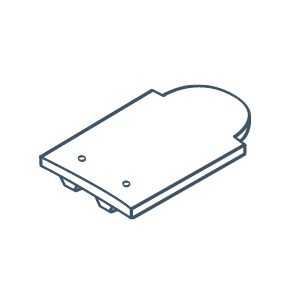

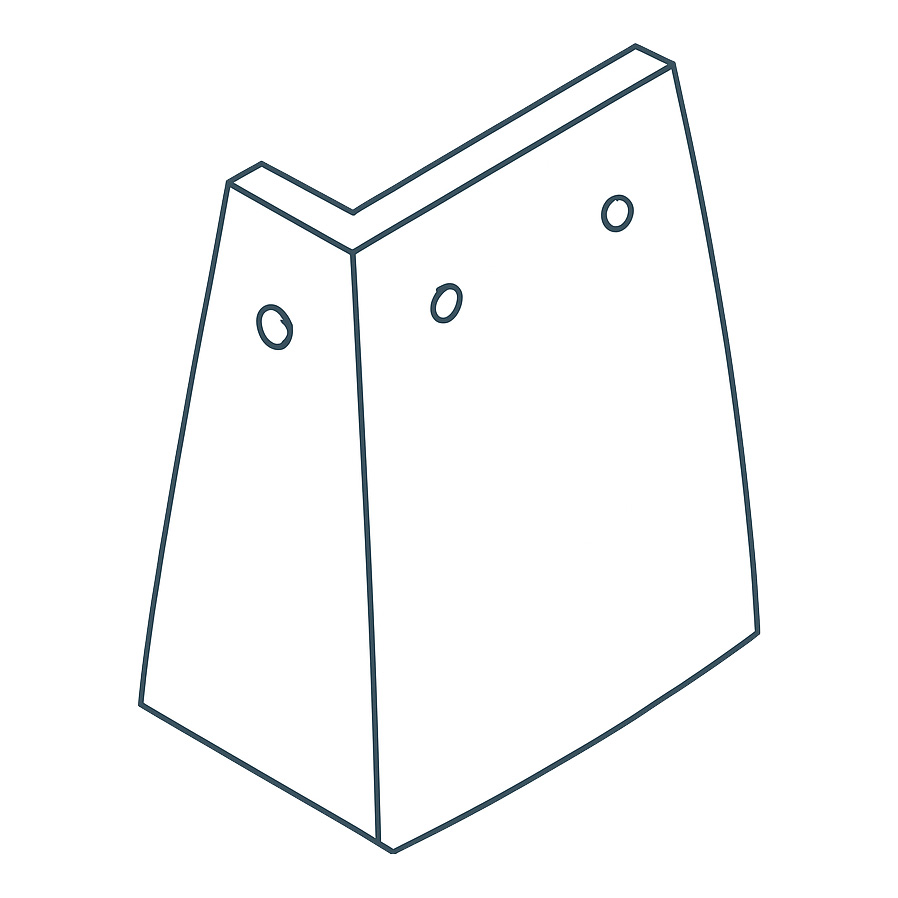

A handcrafted clay tile, showcasing a rich orange tone that brings a vibrant yet timeless charm to any roof.

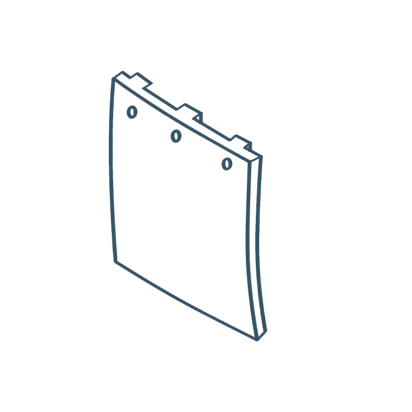

| Roof Tiling | |

|---|---|

| Minimum roof pitch | 40° |

| Headlap (minimum) | 65mm |

| Batten spacing at maximum gauge | 100mm |

| Size of Tile | 265 x 165mm |

| Covering capacity | 60 tiles per m² |

| Cover width | 165mm |

| Weight as laid | 75kg per m² |

| Battens per m² | 10m |

| Batten size | 38 x 25mm |

| Nail size/type of tiles | 38 x 3.35 alloy clout |

| Guarantee | 30 years |

| Vertical Tiling | |

| Minimum roof pitch | 75° |

| Headlap (minimum) | 38mm |

| Batten spacing at maximum gauge | 114mm |

| Size of Tile | 265 x 165mm |

| Covering capacity | 53 tiles per m² |

| Cover width | 165mm |

| Weight as laid | 67kg per m² |

| Battens per m² | 8.7m |

| Batten size | 38 x 25mm |

| Nail size/type of tiles | 38 x 3.35mm alloy clout |

| Guarantee | 30 year |

All tiles comply with C E Marking to British and European Standard BS EN 1304, which legislates for externally tested and verified quality of roof tiles. The tiles are independently tested and verified quality of roof tiles. The tiles are independently tested to the following standards by Lucideon (approved by UKAS and the British Standards Institute):

Kilndown clay plain tiles can be used if the pitch of your roof is between 40° and 90° and they are fixed in accordance with the British standard code of practise for slating and tiling BS 5534: 2014. However, if your roof pitch is lower than 40°, please contact us with details of your requirements and it is very possible we can offer a solution to guarantee the use of handcrafted plain tiles down to a pitch as low as 17.5°.

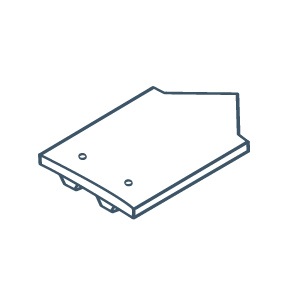

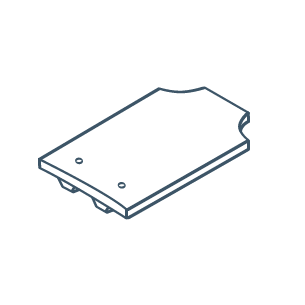

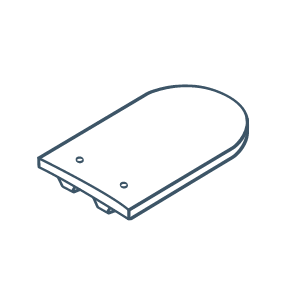

The Kilndown clay roof tile is one of the few handcrafted tiles available on the market today. Each tile is made with varying cambers producing an individuality in appearance and with an excellent selection of colours and blends, there is a Kilndown to suit everyone’s requirements and any roofing project.

Our handcrafted clay plain tiles are used extensively across the UK on refurbishments and new builds alike. Our tiles are widely accepted in conservation areas and regularly used on churches, historic and listed buildings, etc.

Our team of experts is on hand to offer you advice and provide any information you may require. We can give detailed technical guidance and/or general roofing advice over the telephone, by email or during a site visit to suit you individual needs.

The Kilndown roof tiles are produced in Sri Lanka in a modern facility. (The factory is ISO 9001:2008 certificated). The tiles are manufactured by mechanically extruding the wet clay into a ribbon and then forming the tile by hand.

Then during humidity controlled drying a varying cross camber is created in the tile which recreates the texture and imprecision found only on roofs of a bygone era by ensuring no two tiles can be the same shape. They are then fired in modern gas tunnel kilns and packaged in wooden crates ready for shipment.

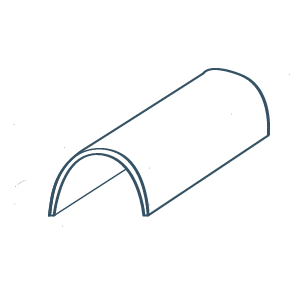

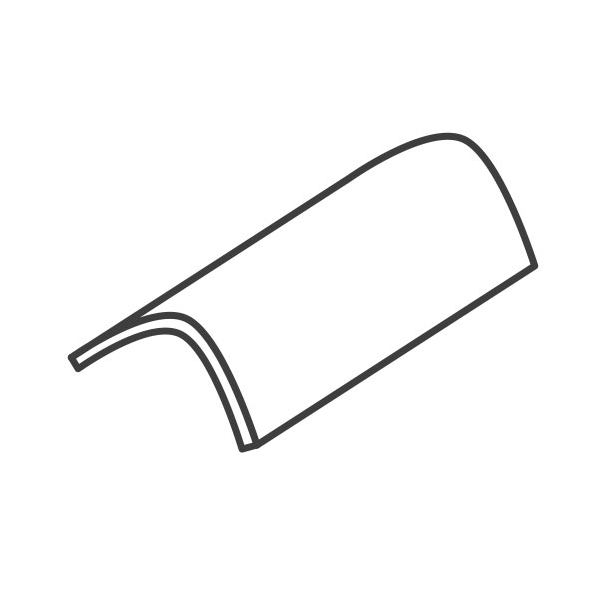

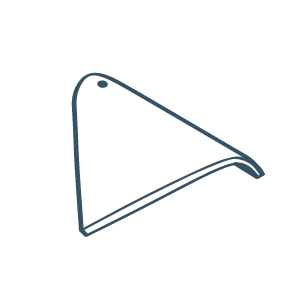

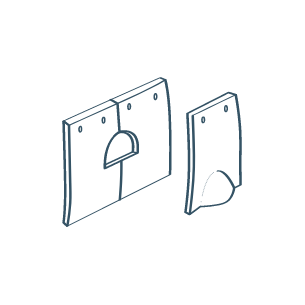

The fittings are formed entirely by hand and then dried and fired in the same manner as the tiles.

Fill out the form below to request a physical brochure.